With its unique and innovative design, the Bettersizer Series (consisting of the Bettersizer S3 and the S3 Plus) combines the measurement methods of static light scattering and dynamic image analysis, thus offering a universal option for characterizing the size and shape of particles from the nanometer to the millimeter range.

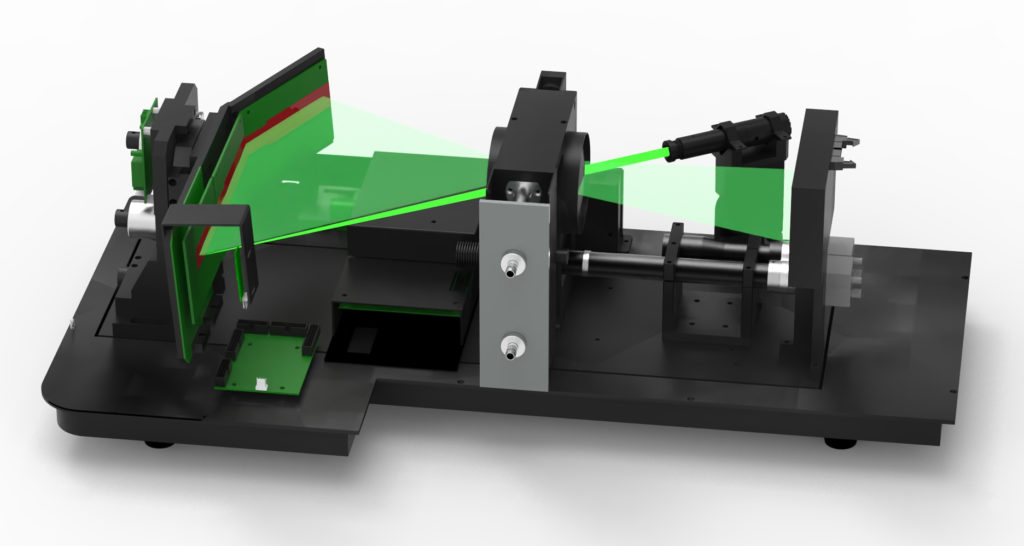

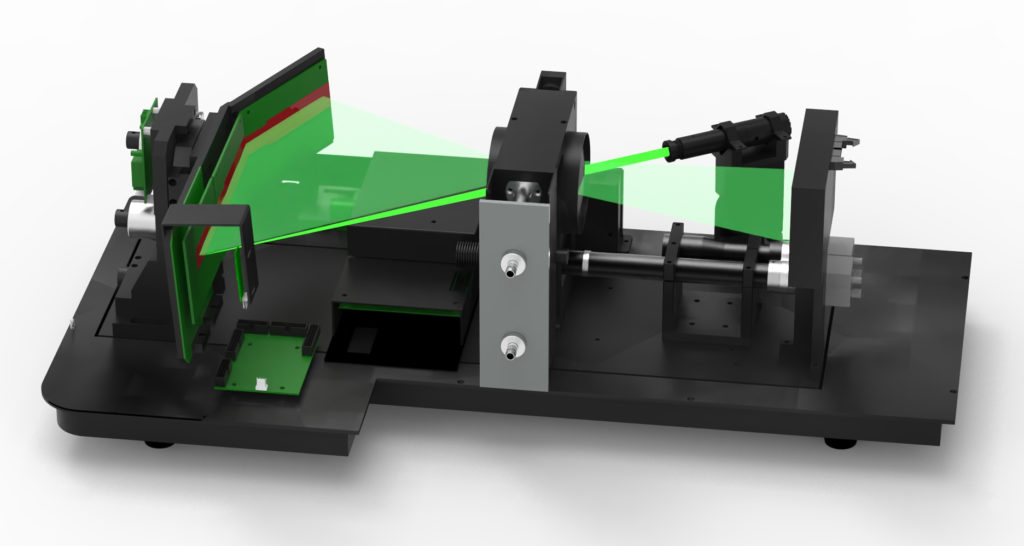

Using the patented DLOI (Dual Lenses & Oblique Incidence) technology, even nanoparticles (from 10 nm onward) can reliably be characterized. The additional lens between the laser and the measurement chamber enables the detection of the backscattered light. The use of only one laser with the oblique incidence of light provides a continuous scattering spectrum with consistent wavelength and allows the detection in a continuous angle range up to 165°.

Since the maximal intensity of the scattered light of large particles can only be detected at very small angles, the classical static light scattering cannot analyze those particles sufficiently enough. The image analysis system of the Bettersizer S3 Plus enables, in contrast to other laser diffraction systems, the reliable detection of larger particles thanks to particle detection by the camera and thus allows realistic measurements up to 3.5 mm.

Thanks to the implemented dynamic image analysis, the most important shape parameters can be calculated from the individual particle images – aspect ratio, circularity, sharpness of edges, and others.

The shape analysis can be carried out simultaneously with the size analysis or independently. Thereby you can choose between two magnifications for image collection (Bettersizer S3 Plus: 0.5X and 10X).

* The measuring range depends on the sample.

Bettersizer S3 Plus – Scheme of Optical Bench (incl. the two CCD cameras)

/1/ ISO 13320 Particle size analysis – Laser diffraction methods

/2/ ISO 13322-2: Particle size analysis – Image analysis methods – Part 2: Dynamic image analysis methods

/3/ ISO 9276-6 Representation of results of particle size analysis – Part 6: Descriptive and quantitative representation of particle shape and morphology

/4/ Particle World 19; p. 4 – 7; “<<The next generation>> in particle measurement: the combination of static light scattering and dynamic image analysis: Bettersizer S3 Plus”

/5/ CIT (Chemie Ingenieur Technik) 4/2018; “Exakte Partikelgrößen- und Formanalyse in einem Messgerät: Kombination statischer Lichtstreuung und dynamischer Bildanalyse” [available only in German]

/6/ Verfahrenstechnik.de, 08/2019, Pressemitteilung: https://www.verfahrenstechnik.de/partikelanalysesystem-besteht-ringversuch/ [available only in German]

/7/ Labo.de, 08/2019, Pressemitteilung: https://www.labo.de/optische-analysengeraete/bettersizer-s3-plus-besteht-erfolgreich-ringversuch-der-bam.htm [available only in German]

/8/ Particle World 20; p. 6-15; “The Bettersizer S3 Plus for particle size analysis – From Gustav Mie to the latest generation of laser diffraction devices”

/9/ CIT (Chemie Ingenieur Technik) 6/2020; „Untersuchung der partikulären Eigenschaften von Sanden hinsichtlich der Eignung zur Betonproduktion“ [available only in German]

/10/ Particle World 21; p. 5 – 8; „Investigation of different sands with the Bettersizer S3 Plus regarding their suitability for concrete production”

/11/ LABO 05/2021, “Qualitätsbeurteilung von Schleifmittelpulvern – Partikelmessungen an einem Korund” [available only in German]

/12/ LABO 05/2023, “Überkornanalyse – Grenzen der Laserbeugung bei der Partikelgrößenanalyse? [available only in German]

The autosampler doses fully automatically up to 60 samples no matter if they are dry powders or pre-dispersed liquid dispersions. The included barcode printer ensures that the results are recorded for the corresponding sample. The sampler is cleaned by ultrasound to avoid contamination.

The BT-80N external small volume dispersion unit is ideally suited for reproducible particle size measurement in polar and non-polar solvents. Due to the small volume of liquid, the consumption of solvent is low. The effective and controllable ultrasonication allows the measurement of difficult to disperse and reagglomerating systems.

Cleaning and a sample or solvent change is very easy due to the quick-lock system. The sample feed to the Bettersizer S3 series is realized via a solvent-resistant tube and controlled manually.

By means of this external, controllable ultrasound option, the measurement of difficult-to-disperse and reagglomerating systems is made possible.

With the online dispersant recycling A.R.U., you can easily and quickly reduce solvent consumption, e.g. of isopropanol.

| Bettersizer 2600 | Static light scattering 0.02 – 2600 µm |

| Bettersizer ST | Static Light Scattering 0.1 – 1000 µm |

| BeNano series | Dynamic Light Scattering 0.3 nm – 15 µm |

| BeVision D2 | Dynamic image analysis 2 µm – 10000 µm |

| DT-100 | Acoustic attenuation spectroscopy 5 nm – 1000 µm |

| DT-1202 | Acoustic attenuation spectroscopy 5 nm – 1000 µm |