Tap density and bulk density of powders

Determination of density by means of gas pycnometry

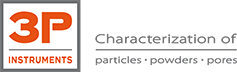

In general terms, density is defined as the quotient of mass and volume. Mass can be determined with ease by a scale. The determination of volume is more challenging, usually due to samples having irregular shapes or being powders of varying degree. Additionally, it needs to be noted that volume, and thus density, may be defined differently if pores are included (raw density) or excluded (true / absolute density) into the solid samples volume. The density is based on the solid samples volume excluding the pore volume of porous solids.

Definition of different volume terms

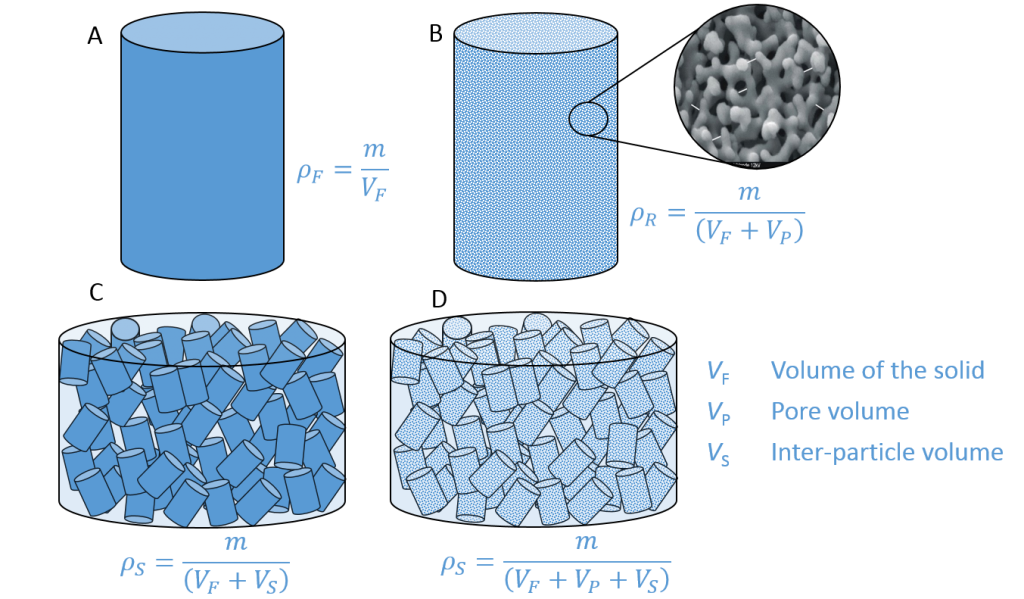

With a pycnometer (Greek, „gauged vessel”) the amount of a certain medium (liquid or Helium or other analytical gases) displaced by a solid can be determined. Examples for the use of density determinations for finely ground or bulky solids include, but are not limited to, for example the differentiation between solids, quality insurance, determination of open and closed pore volume in foams and determination of so-called vacuolar volume in the quality control of milk powders. These fields illustrate the versatility of gas pycnometry and exceed the limits of liquid pycnometry. The main advantages of the gas pycnometry are:

- fast

- precise

- requires no organic liquids

- low user expense

- automatization

Schematic measurement setup

Tap density and bulk density of powders

If a powder is loosely poured into a measuring cylinder the bulk density can be determined. Bulk density considers existing pores and the interparticular voids of a loose powder bed. The tap density of powders after defined tapping steps of the powder bed can easily be calculated. Tap volume and density also consist of pores and interparticular voids, which are not based on a loose powder bed but on a bed after a defined number of tapping steps. The method for tap- and bulk density determination requires an easy measuring arrangement but leads to important material properties for storage and transport applications of powdered and bulk samples.

Measuring method

Measuring instruments for the determination of tap densities are called tap volumeter, such as the BeDensi T Pro series. This is a small devices with one, two or three rotary plates. The cylinder can be used to determine the bulk volume before tapping the sample and therefore gives information how compressible the material is. The tapping number is set and automatically finished after that.

A tap starts with raising the rotary plate automatically including the filled cylinder followed by dropping it, which results in compacting of the powder bed. The volume of the sample decreases during the tapping procedure. Therefore the tap density is higher than the bulk density.

Deutsch

Deutsch English

English